Maintaining lubricant quality is an important step to keep machinery and equipment running smoothly. The poor control of the oil storage process may further lead to lubricant contamination, inefficiency, and a short life of machine components. Choosing the right lubricant storage solution is a vital first step toward ensuring that lubricants remain in optimal condition and extend the lifespan of your equipment.

The iCan Fluid Transfer System comes as one of the perfect solutions for oil storage and lubricant handling. Our product line has been designed to meet the needs of the modern industry through innovations in lubricant storage, transfer, and usage. With iCan Fluid Transfer System, you can protect your lubricants throughout storage and usage, ensuring safety and efficiency in your operations.

This guide outlines the steps to select a lubricant storage solution that aligns with your specific requirements, enhancing efficiency and reducing the risk of lubricant degradation.

Step 1: Understand Your Lubricant’s Specific Storage Requirements

Evaluate The Type of Lubricant:

Storage requirements vary depending on each type. A proper understanding of storage tips right from the beginning will save you avoid mistakes that may lower the performance of the lubricant. For example, base mineral and synthetic lubricants require different treatments with respect to temperature and humidity to remain stable. Storing lubricants carelessly generally results in quality degrading, which, in turn, causes damage to the engine and increase operational costs.

Temperature and Humidity Considerations:

Proper oil storage should consider the immediate environmental conditions, especially those of temperature and humidity. There are certain lubricants that would be sensitive to extreme fluctuations in temperature or even just exposure to humid air that can result in oxidation of the same, influencing quality. Therefore, storage in a controlled space is quite essential. A perfect storage system will maintain the temperature at a constant level and prevent the lubricant from environmental contamination.

Avoid Contamination Risks:

Contamination is a major concern in lubricant storage. Containers should be tightly sealed and leak-proof to prevent the entry of dust, moisture, or foreign substances. iCan’s Fluid Transfer System offers a storage solution that safeguards lubricants against contamination, ensuring they remain in optimal condition up to the point of use.

Step 2: Choose the Right Container Size and Material

Size Considerations:

Selecting the right container size is essential for effective lubricant storage. Small containers are suitable for low lubricant consumption, as they reduce the chance of degradation. For high-volume use, larger containers reduce the frequency of refilling, which can improve operational efficiency.

Container Material:

Consider container materials carefully. Metal containers are durable and ideal for industrial environments but may not be suitable for oxidation-sensitive lubricants. Plastic containers are lightweight and cost-effective, offering excellent resistance to fluids, but compatibility with the lubricant type is essential to prevent chemical reactions that could affect quality.

Compatibility with Lubricants:

Ensuring compatibility of the container material with the type of lubricant stored will be key to maintaining quality. Certain types of lubricants, especially synthetics, may have particular chemical properties that could react with some materials. Knowing such properties is what will help you avoid issues such as discoloration, viscosity, and deposits forming in the lubricant. The proper storage solution will keep lubricants optimal until use.

The iCan Fluid Transfer System offers a versatile selection of fluid transfer containers, available in 2L, 5L, and 10L sizes, to meet a variety of storage needs. Each container size is designed to handle specific storage volumes, making it easy to select the perfect fit for your operation.

Additionally, iCan containers can be customized according to specific requirements, ensuring that each lubricant type is stored safely and effectively. With options tailored for different lubricant classes, iCan’s fluid transfer containers provide reliable protection against contamination and are built to maintain lubricant integrity over time, enhancing overall efficiency and safety in fluid management.

Step 3: Implement Proper Labeling and Identification Systems

Clear Labeling for Lubricant Types:

Clear labeling is essential in lubricant storage to prevent the incorrect application of lubricants, which can damage machinery. Labels should include important information like lubricant type, viscosity, and intended application, enabling quick identification and accurate use.

Color Coding and Tagging Systems:

Color coding or using special marking systems is one of the perfect solutions to lubricant identification. In color coding, an operator identifies the right type of lubricant used instantly without having to read each label in detail. The practice also helps minimize human error and speeds up different operations. For instance, you can use blue for synthetic-based lubricants and red for mineral lubricants, which guarantees efficiency in selection and application.

Tracking Lubricant Age:

Tracking lubricant age is crucial, as expired lubricants can impair performance. Labels should include production and expiration dates to facilitate stock rotation, ensuring older lubricants are used first. iCan’s Fluid Transfer System includes integrated tracking features that make container management easy, optimizing lubricant usage and performance.

The iCan Fluid Transfer System offers an all-in-one solution for optimal lubricant labeling and identification, making fluid management simpler and more efficient. Each iCan product includes a 10-color iBand Kit and an iTag Kit, which can be placed directly on the lid to provide instant, color-coded identification.

This system helps users quickly distinguish between different lubricants, reducing errors and improving efficiency. Additionally, iCan offers the iPouch, a convenient pocket for notes. On the iPouch, users can record important details like the lubricant name, purchase date, and expiration date, ensuring that vital information is always accessible. These labeling tools make it easy to track and identify lubricants, supporting precise and organized fluid management.

Step 4: Design Efficient Storage Layout and Accessibility

Organized Storage System:

A well-planned layout is the most crucial issue related of perfect storage for lubricants. An efficient storage system allows quicker access but reduces the occurrence of mistakes and speeds up, overall, the process of operation. You are able to place lubricant containers in order from type and frequency of use to reduce time spent in searching for containers and for proper lubricant application practices. These practical storage tips go a long way in ensuring work efficiency.

Stackable and Portable Storage Solutions:

Space-saving, stackable, and portable oil storage facilitates maximizing space, especially when the inventories’ storage or keeping space is limited. The ability to stack containers vertically saves space and maintains safety, provided the containers are stably stacked. Aside from this portable system, which easily caters to the removal of lubricants when needed without placing the operator in danger, the flexible design allows you to maximize your valuable storage space without compromising safety.

Accessibility for Routine Maintenance:

Accessible storage is essential for efficient inspections and maintenance. Containers should be easy to reach for routine monitoring, refilling, or preventive maintenance, helping keep lubricants in peak condition and operational efficiency high.

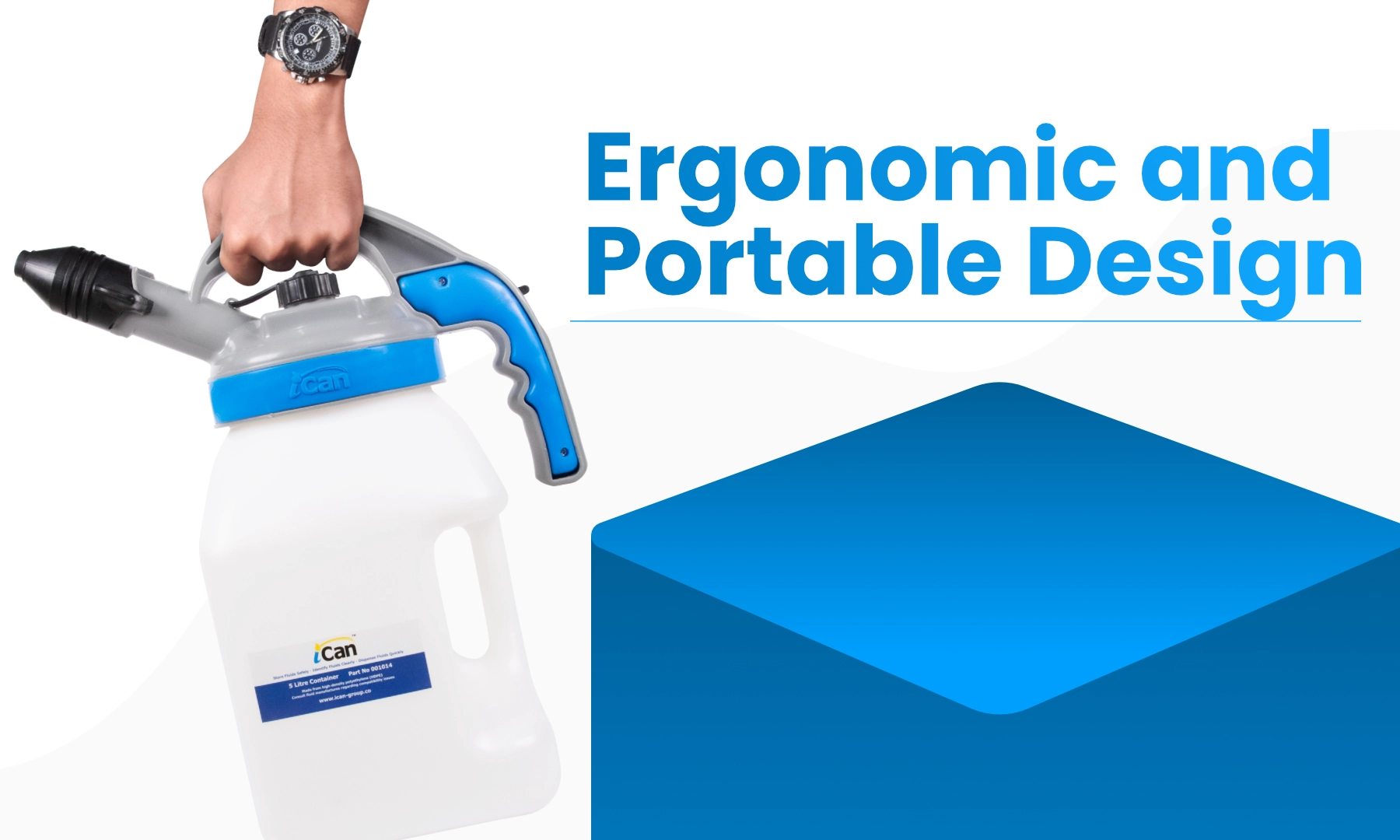

The iCan Fluid Transfer System features smart storage solutions that optimize space while ensuring seamless accessibility. Their ergonomic design makes them highly portable, allowing users to easily carry and move them as needed. Whether transporting lubricants across workstations or taking them into challenging environments, iCan products provide both convenience and efficiency, supporting flexible fluid management in any workspace.

Step 5: Prevent Contamination with Sealed and Secured Containers

Ensure Airtight Storage:

Airtight containers are essential for protecting lubricants from contaminants like dust and moisture. Properly sealed containers prevent the entry of foreign particles that can degrade lubricant quality and impact equipment performance.

Secondary Containment Options:

Secondary containment systems, such as retaining plates or drip trays, prevent spills and leakage, safeguarding the storage area and reducing waste. These containment solutions are especially valuable for storing petroleum products safely.

Automated Transfer Systems:

Automated transfer systems minimize human interaction during lubricant transfers, reducing contamination risk. iCan’s Closed-Loop Fluid Transfer System enables secure lubricant transfers, protecting lubricant purity and ensuring efficient, safe operations.

The iCan Fluid Transfer System offers robust protection against contamination, ensuring lubricant purity throughout storage and transfer. Equipped with a smart lid system, iCan containers allow for quick and easy fluid identification and are designed with user-friendly, ergonomic features for enhanced comfort.

The Pour Lid and Storage Lid are fitted with two quick ports and a desiccant port plug, allowing for hose or extension hose attachments without the need to fully open the lid. This feature effectively minimizes exposure to contaminants, maintaining the integrity and cleanliness of the lubricant. With iCan’s smart lid system, your lubricants remain safe from contamination, promoting reliable and efficient fluid management.

Enhancing Operational Efficiency with Effective Lubricant Storage Solutions

Effective lubricant storage is critical to preserving lubricant quality and equipment performance. By following these steps—understanding lubricant requirements, choosing the right container, implementing labeling systems, designing efficient storage layouts, and preventing contamination—you can enhance operational efficiency and reduce potential damage.

The iCan Fluid Transfer System offers a complete solution for reliable lubricant storage and handling. With airtight systems and automated transfer technology, iCan ensures that every stage of storage and transfer is managed with precision and care. Contact iCan today to learn how our solutions can enhance your lubricant storage practices, protecting your investments and boosting equipment reliability.